Key Buying Points

-

01

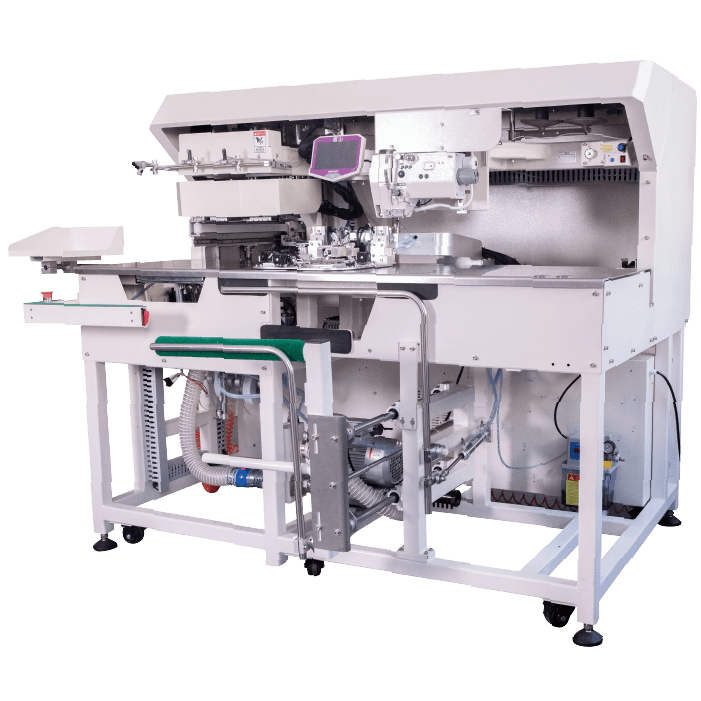

The same shape of the patch pocket only needs a pair of molds, can deal with the smallest size to the largest size of the pocket, knitted, woven, denim patch pocket are applicable.

-

02

Completely subvert and solve the production cost of bag molds of different specifications and the waste of time in storage, replacement and testing.

-

03

Efficiency is significantly improved, with an average of one bag completed every 12 seconds.

-

04

The cost is significantly reduced, compared with the input-output ratio of traditional bag paste machine customers, and the full life cycle is reduced by 10 pairs of molds, saving at least 2000 USD.

-

05

The application is convenient and easy, with the replacement mold debugging time 30 minutes, the whole life cycle replacement30 times, the time saving cost is more than 2000 USD.

-

06

Compared with manual pocket setting, one person can replace the original three people's output and the quality is beautiful; The return on the investment of the user, the investment is recovered within one year, and the profit is increased by 20,000 USD per year.

Product Specifications

| Model | Needle Gauge | Needle | Max. Production Capacity | Rated Power | Operating Air Pressure | Net Weight | Sewing Speed | Packaging Dimensions |

| HI-23-23/M | Standard 2.5mm Optional 0-12.7mm |

DBx17 | 2.5MM.150Needles 300Packages/1小时 |

0.7KW | 5bar | 787KG | 4000 | 665x260x570mm |